-

Onye-nkwụsị ngwọta

Elekwasị anya na ọgwa na mmepe, anyị na-ewu ezi mmekọrịta na ígwè factory, webbing èbè factory, pole ngọngọ factory, ibu binders factory na igwe anaghị agba nchara ngwaahịa factory, iji hụ na ndị dị iche iche mkpa nke anyị na ndị ahịa na kacha mma mma na asọmpi price. -

20 afọ ahụmahụ

Anyị na rigging ụlọ ọrụ ruo afọ iri abụọ. Anyị bụ ndị ezigbo Nchikota stocking, sourcing, nkwakọ, uru kwukwara ọrụ. Inye quality eri irè ngwọta ahaziri gị onye mkpa. -

elu àgwà

"Quality mbụ, Ahịa mbụ", anyị hụ ọ bụla ngwaahịa rue nnyefe nnyocha. Anyị na-eme mgbalị nile iji nye elu àgwà na asọmpi price. Nchekwa gị bụ nchegbu anyị.

Linyi Égbè Eluigwe rigging CO., Ltd e hiwere na 1998, emi odude ke Linyi City, Shandong Province. Anyị factory na-pụrụ iche na akara nke rigging hardware, anyị na-enye dịgasị àmà nke ngwaahịa, dị ka waya eriri mkpachị, nkpọrọ olu, turnbuckles, nko, yiri mgbaaka, thimbles, aka uwe na otú on.Focus na ọgwa na mmepe, anyị na-ewu ezi mmekọrịta na nkpọrọ factory, webbing èbè factory, pole ngọngọ factory, ibu binders factory na igwe anaghị agba nchara ngwaahịa factory, iji hụ na ndị dị iche iche mkpa nke anyị na ndị ahịa na kacha mma mma na asọmpi price.

-

Standard for inspection of ring of steel ...21-01-15Steel wire rope sleeve ring, which can also be called the heart ring, it is a kind of lifting machinery. Therefore, it is widely used in the field of heavy industry hoisting. Then the following is a brief introduction of its inspection standards by Piner superior industrial equipment, so that we can understand, and at the same time, but also can increase their own knowledge of steel wire rope. The inspection standard of steel wire rope set ring, its main, is four: (1) steel wire...

-

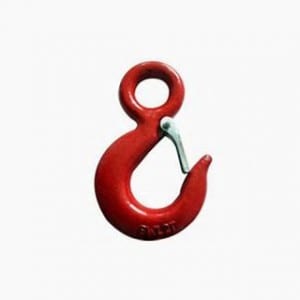

Selection and safe use of sling20-12-30The hooks are forged from carbon structural steel or alloy structural steel and heat-treated, and have the characteristics of small volume, light weight and high strength. The strength classes of hooks are M (4), S (6) and T (8). The hook test load is 2 times the limit working load, and the breaking load is 4 times the limit working load. Main purpose and scope of application The hook is mainly used as a connecting tool in lifting operation. Use and operation The limit working load and applic...